About us

ENERGOREMONT Sp.

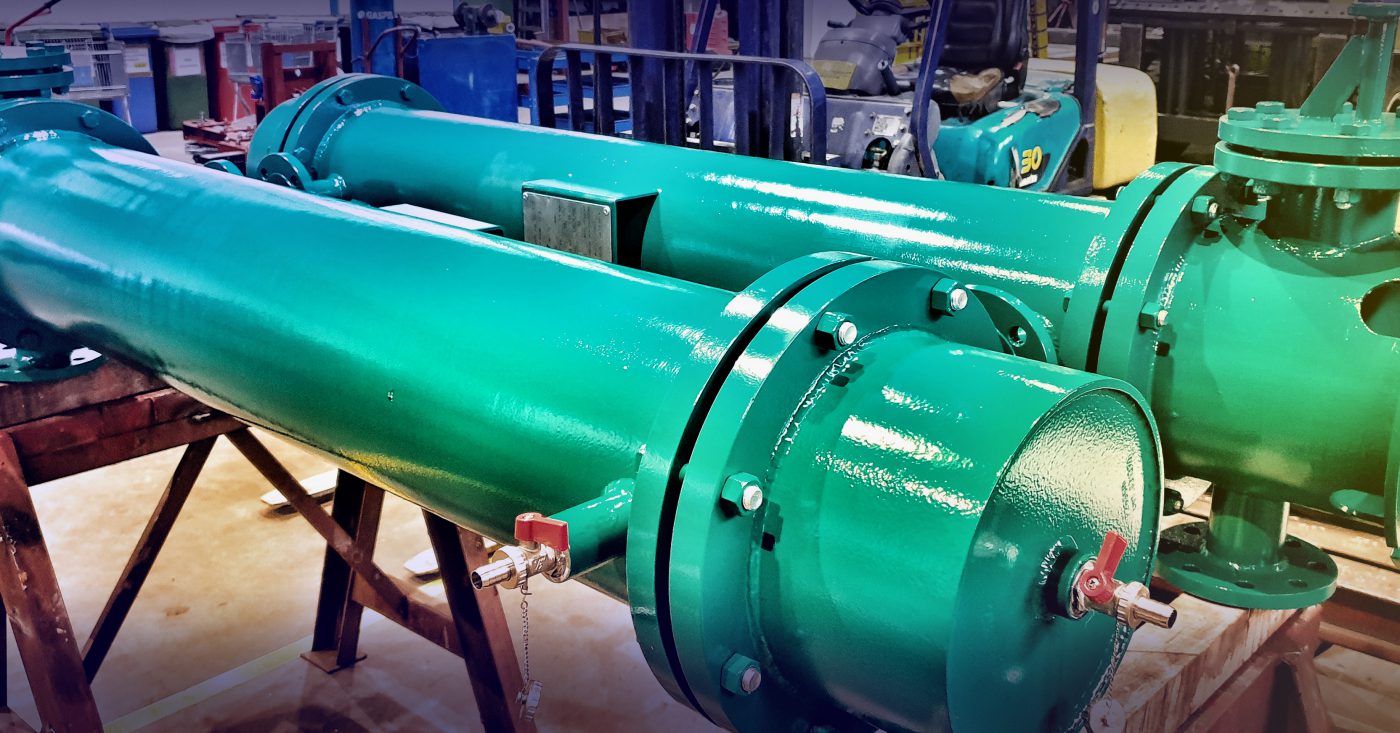

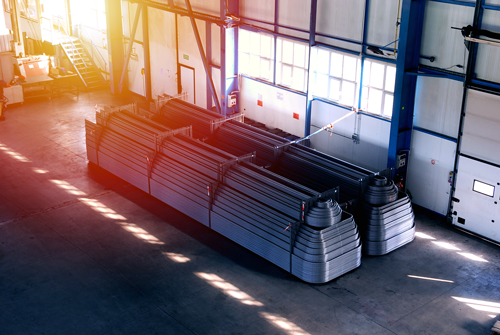

z o.o. is an engineering company with many years of experience specialising in manufacturing, retrofit and overhaul of shell and tube heat exchangers commonly used in large-scale energy generation, as well as in the paper, chemical and sugar industries.

All types of coolers, turbine condensers, heaters, evaporators, chemical equipment, disposal equipment and other heat exchanger systems should be fault-free if they are properly designed and assembled – and this is precisely what ENERGOREMONT Sp.

z o.o. does.

What we do

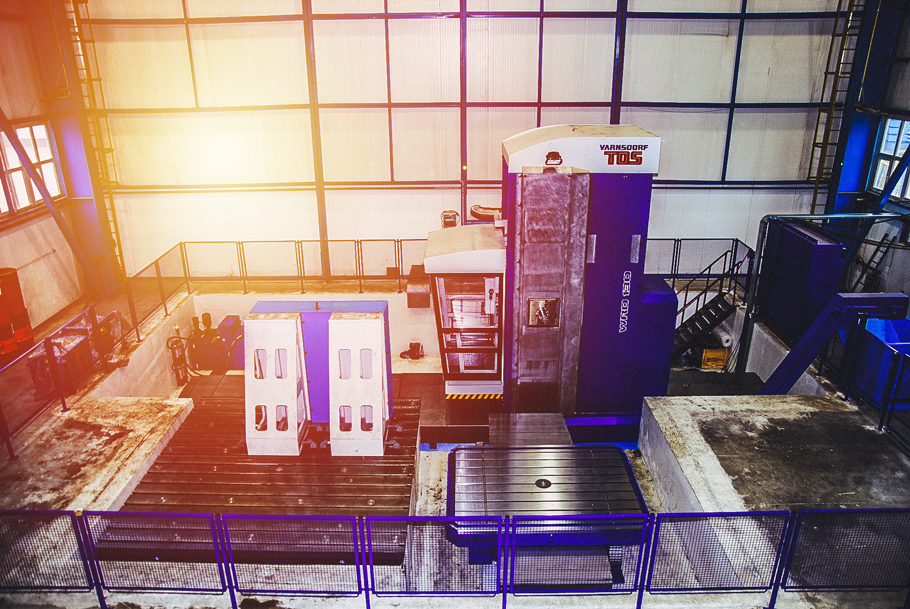

ENERGOREMONT Sp. z o.o. specialises in manufacturing, retrofit and overhaul of shell and tube heat exchangers based on its own patented technology and its own tools. The company has its own specialist equipment, a fleet of assembly vehicles and modern production facilities, which enable the independent execution of tasks both on site and at the customer’s premises, with total control over the timeliness, quality and cost of implementation.

The scope of the company’s business can be divided into four basic industries:

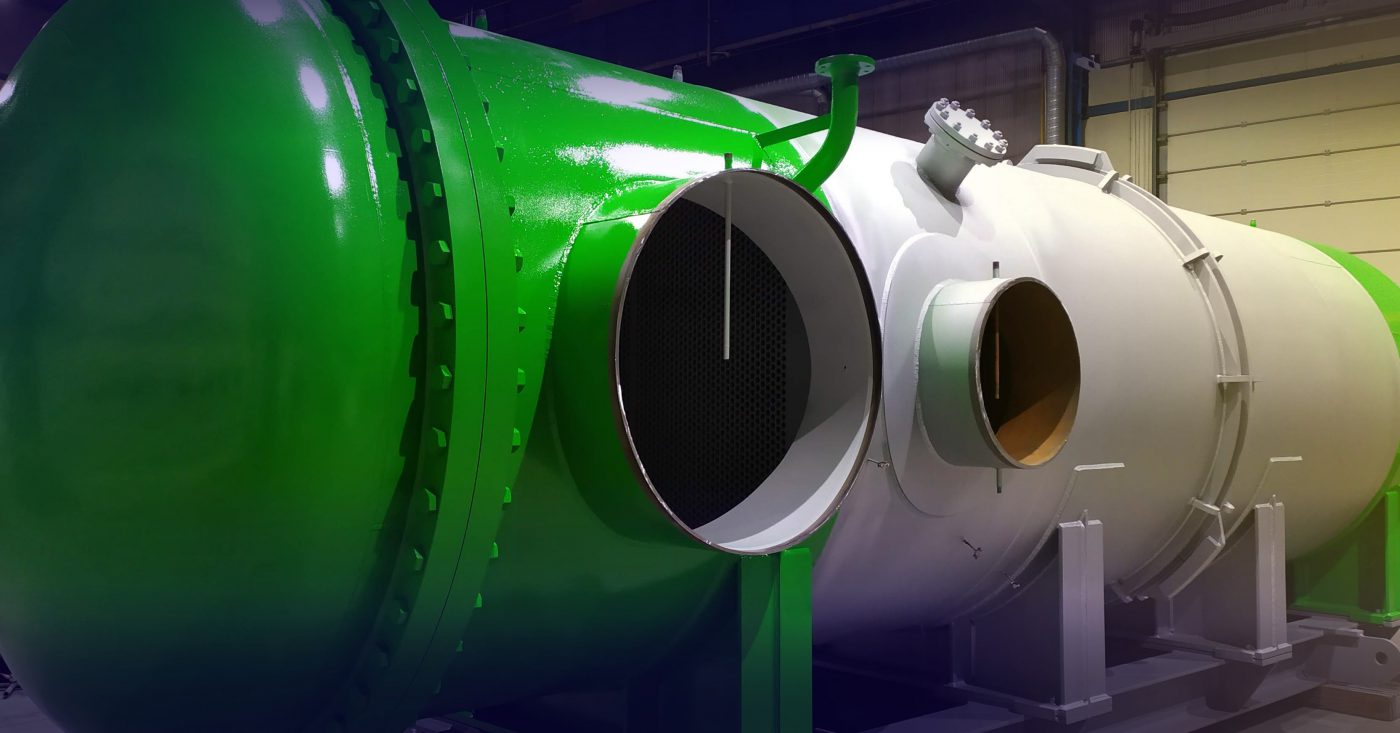

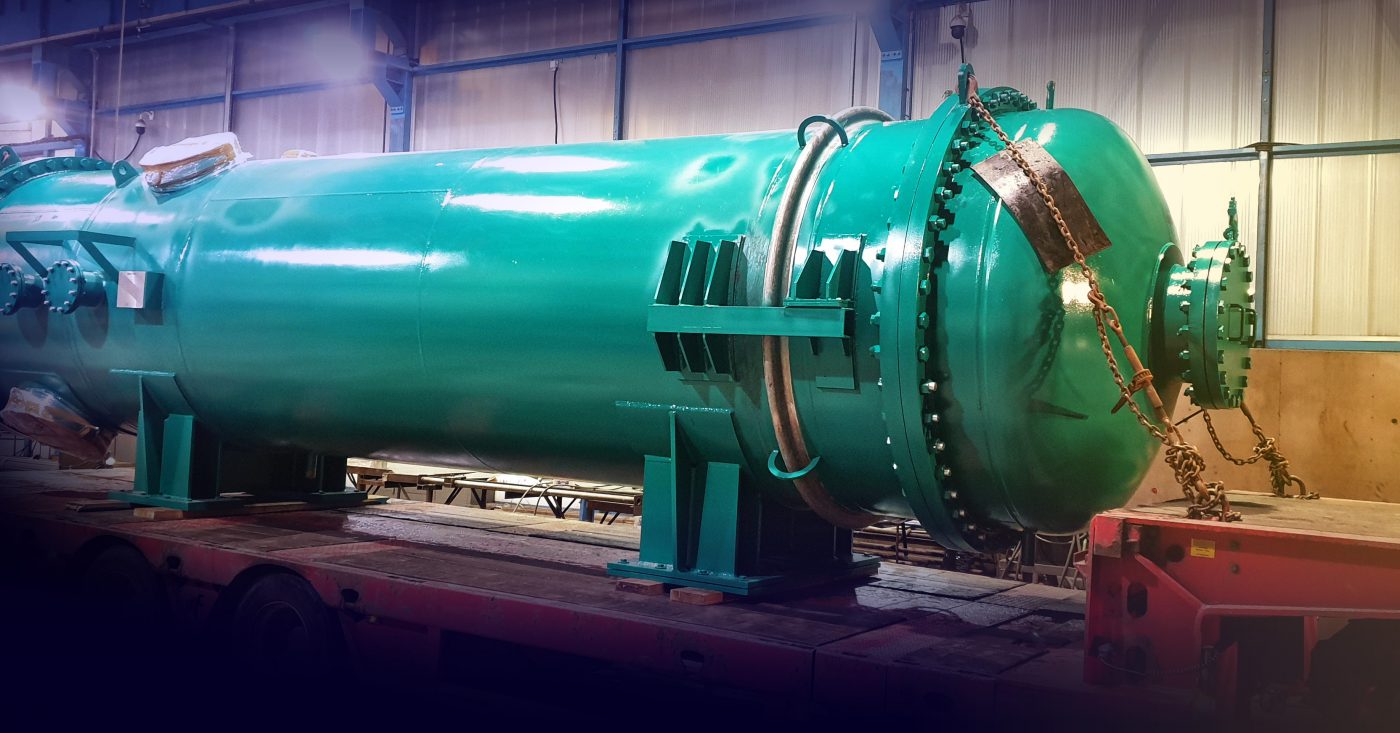

Comprehensive manufacturing, retrofit and overhaul of shell and tube heat exchangers

Proprietary patented overhaul technology enhanced by modern production technology

Trained and experienced engineering staff, the highest quality standards and attention to the environment and safety

Technology

Energoremont Sp. z o.o.’s

portfolio is based on its own patented overhaul technology supplemented with modern production technologies.

It covers in particular: tube disassembly technology, new tube installation technology, special tube-to-tube-sheet joints, emergency supplementary technologies for overhaul and retrofit, and technologies for manufacturing and overhauling equipment under production conditions.

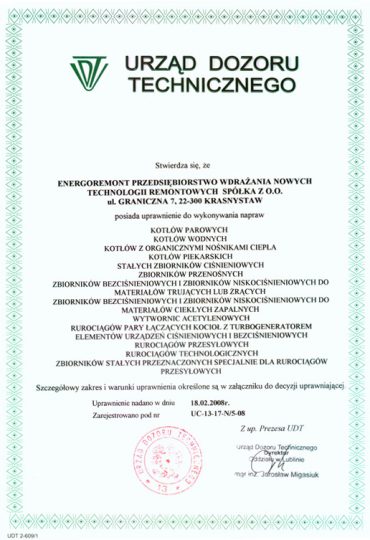

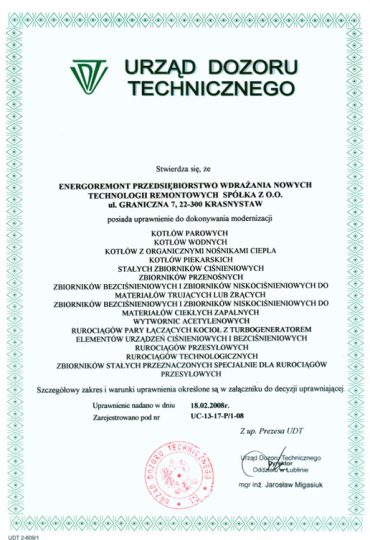

Authorisations

- steam boilers

- water boilers

- boilers with organic heat transfer media

- bakery boilers

- fixed pressure tanks

- portable tanks

- non-pressure and low-pressure tanks for poisonous or corrosive materials

- non-pressure and low-pressure tanks for flammable liquids

- acetylene generators

- steam pipelines linking boilers and turbine generators

- components of pressure and non-pressure transfer piping equipment

- process pipelines

- fixed tanks specially designed for transfer pipelines

- steam boilers

- water boilers

- boilers with organic heat transfer media

- bakery boilers

- fixed pressure tanks

- portable tanks

- non-pressure and low-pressure tanks for poisonous or corrosive materials

- non-pressure and low-pressure tanks for flammable liquids

- acetylene generators

- steam pipelines linking boilers and turbine generators

- components of pressure and non-pressure transfer piping equipment

- process pipelines

- fixed tanks specially designed for transfer pipelines

- components of pressure and non-pressure equipment

- non-pressure and low-pressure tanks for poisonous or corrosive materials

- non-pressure and low-pressure tanks for flammable liquids

- components of pressure and non-pressure transfer piping equipment

- fixed tanks specially designed for transfer pipelines

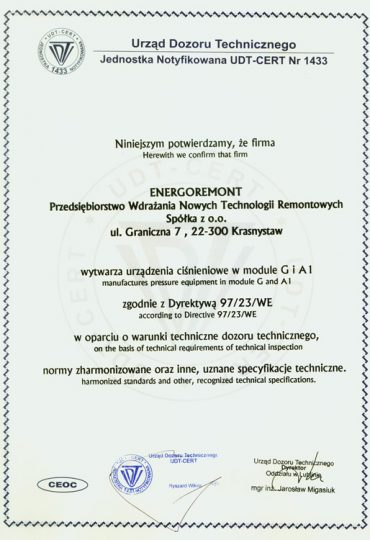

- confirming the company’s ability to manufacture Module G and A1 pressure equipment in accordance with Directive 97/23/EC based on technical requirements for technical supervision

Quality policy

The Integrated Management System implemented at ENERGOREMONT Sp. z o.o. combines three systems: a Quality Management System as per ISO 9001, an Environmental Management System as per ISO 14001 and an Occupational Health and Safety Management System as per BS OHSAS 18001.

It provides a documented and coherent framework that enables efficient company management through the establishment and implementation of a uniform policy and resulting objectives.

Contact details

- ul. Graniczna 722-300 Krasnystaw

- 82 576 67 80

- fax 82 576 28 25

- energoremont@energo.com.pl

GPS coordinates

N 50° 58.833

E 023° 09.384

Bank account

- BGK No. 53 1130 1206 0028 9174 5620 0001

Registration data

District Court Lublin-Wschód in Lublin with registered office in Świdnik, VI Commercial Division of the National Court Register

KRS: 0000056540

NIP: 712-015-78-02

REGON: 008056359

Share capital: PLN 540,090.00